|

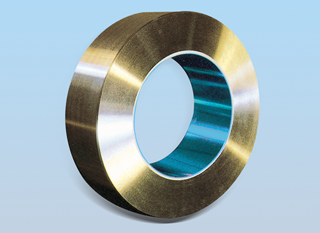

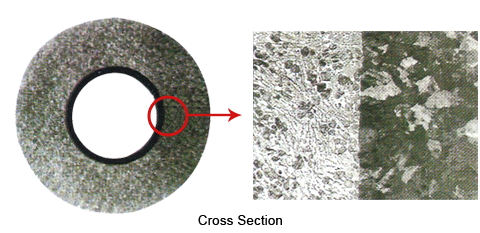

01Bimetal Cylinder

Bimetal Cylinders are provided with special alloy layer (2 mm) on the inner surface of cylinder by heat treatment to improve mechanical properties of the base metal, increase allowable pressure, and provide excellent hard layer and wide strength range in the operating window. Different from nitriding, the hardening thickness can be controlled freely. The cylinder base metal and special alloy can be selected according to the operating conditions.

Classification of Bimetal Alloys

| Alloys |

H-102 (Fe) |

H-305 |

H-507 |

H-503 (Ni) |

H-60 |

H-70 |

H-801 |

H-802 (W) |

|---|

| Feature |

For abrasion resistance |

For fluoroplastics |

For abrasion resistance |

For abrasion resistance |

For high abrasion resistance |

For ultra abrasion resistance |

For high abrasion resistance |

For ultra abrasion resistance |

|---|

| For anti-corrosion |

For anti-corrosion |

For anti-corrosion |

For anti-corrosion |

For anti-corrosion |

| Composition |

Fe-Ni-B |

Ni-Cr-Si-B-Cu |

Co-Cr-B |

Ni-Co-Cr-Si-B |

Ni-Co-Cr-Si-B+ |

Ni-Co-Cr-Si-B+ |

Ni-Cr-Si-B |

Ni-Cr-Si-B+ |

|---|

| Special carbide |

Special carbide |

Special carbide |

Special carbide |

| Hardness (HRC) |

55~65 |

45~53 |

45~58 |

50~60 |

53~62 |

55~64 |

55~63 |

60~67 |

|---|

| Longitudinal Modulus Gpa(Kg/㎟) |

181.4(18500) |

205.9(21000) |

196.1(20000) |

205.9(21000) |

215.7(22000) |

215.7(22000) |

205.9(21000) |

205.9(21000) |

|---|

| Thermal Expansion Coefficient /℃(15~250℃) |

10.0X10-6 |

13.0X10-6 |

11.6X10-6 |

11.8X10-6 |

11.4X10-6 |

11.2X10-6 |

11.5X10-6 |

10.5X10-6 |

|---|

| Thermal Expansion Coefficient /℃(15~400℃) |

10.5X10-6 |

13.5X10-6 |

12.1X10-6 |

12.5X10-6 |

12.0X10-6 |

11.8X10-6 |

12.0X10-6 |

11.0X10-6 |

|---|

|

|